Bigger isn't always better they say, I wish we'd listened to that advice before putting a huge bit of industrial machinery into our not-so-big bedroom......

When we returned home from long-term travelling in May, we decided to make a big change to our lives. In a-roundabout-way we returned to what we enjoyed most as youths, creativity. It’s not that we didn’t follow creative routes in our careers, but as in most creative endeavours to make ends meet, a sacrifice was needed. In Ali's case, her job was to create something for the fast fashion market; make it cheap, make it quickly, and link it to current trends. This was an 8 and a half year endeavour, working for some of the biggest names on the highstreet. For me, I tried to inspire the next generation to get hands on, create, fail, learn from failure and create again. Teaching is a noble cause in many ways, but rather selfishly, left little time for my own projects.

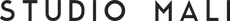

The laser bed

We both decided we wanted to create objects that people would find both beautiful and useful. We didn’t know exactly what that would be, but stepping into the unknown is a key part of the creative process. Paramountly, we hadn’t considered how we would make these objects! Living in the eaves of a Victorian house doesn’t leave a whole of lot of space for making things. To put it into perspective, my school workshop has a band saw, rotary sander, fret saws, every hand tool going and huge tables to construct on. The question we posed was “how could we ever make things in our second story flat?” The answer took the form of a large and noisy industrial machine from China. A laser cutter.

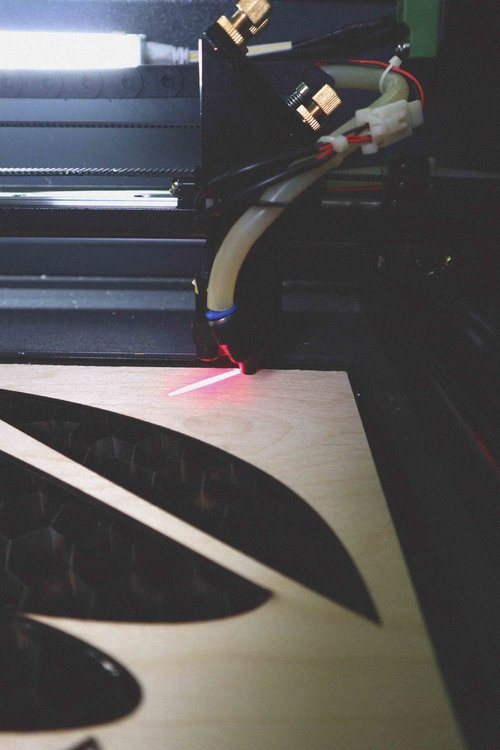

The x and y axis is like a robotic arm controlled by the computer

I assume that most people have of heard of a laser cutter? If not then imagine an intense beam of light that can cut through materials on a X,Y and Z axis, meaning it can travel north, south, east and west and up and down across a large metal mesh where the material is placed. We knew it was the only way we could make complex detailed projects in out flat, without turning a room into a messy workshop and becoming the worst neighbours in Hackney.

Our workstation

We researched for months and nearing the end of our trip we purchased a machine that would fit into the flat, a desktop machine apparently. After a months lead-time, the machine was delivered and our jaws hit the floor when we discovered the size of it. Abu turned up at 8am with van full of equipment; cutter, chiller, extraction, laser tube and huge steel lathe attachments. Totally fazed by the challenge ahead, we also learned that Abu had hurt his back the week before and had assumed Ali was a strong man that could lift it with Mark, wrong! We all stood dumbfounded at the challenge ahead. The machine was huge, weighing 76kg and would barely fit through a door let alone turn the tight corners of the corridors leading up to the flat. In shock, we rang a few removal companies who each brazenly quoted £100 for 5 minutes work. Abu recommended paying some passers by and as we scanned the horizon who would turn the corner but Hackney’s finest rubbish collection team, our saviours.

Ali put on her best damsel in distress wide-eyed-help-me-face on and before we knew it 3 burly bin men had rammed, scratched and dented every internal wall to get the cutter up into the flat. They seemed happy with the £20 quid reward but just as happy that they could help us. We were ecstatic it could even fit in the flat! A few hours of installation and a bit of dodgy health and safety from Abu (who advised us not to wear the safety glasses when the door was open) and we were up and running with a 50watt CO2 laser cutter humming away in our bedroom. It was a surreal day.

So what is it like living with an industrial laser cutter in your bedroom? We can tell you that even with extraction that pumps out all the smoke and debris, cutting plywood all day creates an inescapable burnt odour in the room. The noise is similar to a hoover, which is bearable, whilst, the piles of materials stacking up around machine seem to become entangled with your end-of-the-day pants and socks. Do we have a bedroom anymore? Nope, not really. More like a trendy manufacturing come flexible workspace with added bed!

For all its negatives, the laser cutter has allowed us to move closer to our dream of starting a little business of our own, you may have noticed a shop appear on the website. The laser cutter has meant we can make an array of projects in-house or in-flat as the case may be. Ali has become public manufacturer no.1 with her array of necklaces and wall hangings! Our lives have been altered by the little piles of burnt plywood ready for sanding, but that’s exactly how we like it. Moving one step closer to our dream.

PIN IT!

(Finders keepers)